|

|

Powerful Monuments

It's just a matter of time before an oil well "goes on the pump". Even yesterday's mighty giants which started out by blowing the oil over the derrick finally tamed down into pumpers. And those which have reached settled production while on the pump may carry on at only a fraction of a barrel per week. At least that is the common story in the stripper oil belt of Pennsylvania. Most shallow Upper Devonian oil sands in those fields were pressure-depleted long ago.

Eaton (1866) wrote of pressure depletion as he observed it in the Oil Creek region in the 1860's, "...as the number of wells bored in any given locality increases, the number of flowing wells will decrease, until they cease altogether." He went on to state that "...like the bow that has been held too long in tension, its power will be lost, and pumping wells must be the final dependence." Pumps came to the rescue. The first pumping was done by water wheels, boilers, even mules. A hand pitcher pump (farm water pump) served when Drake brought in his 1859 well. Steam-powered central pumping units arrived about 1880. Natural gas from the oil lease wells replaced steam as soon as engines were developed to handle it. Gas engines became common in the mid 1890's and drove many powers (still do).

The heart of many of these old leases is the central power, simply called the "power". It is often located in a central position in the lease. The duty of the power is to provide the motion to pump multiple wells over a suitable radius. The pumping wells are distributed around it, evenly or awkwardly depending on how the operator had to fit the power with respect to existing wells. A single power may pump over 50 wells, but the usual amount is 36 wells or less (often much less). The wells must be closely spaced and in terrain which does not block their connection to the power.

Powers in the Appalachian Basin were made by many companies, some of them in local oil towns such as Oil City, Titusville, Franklin and at other forges and factories throughout the region. The same can be said for the engines that ran the powers. Most old, defunct oil belts are veritable museums of the equipment of the oil industry. Powers are powerful artifacts in this old industrial array.

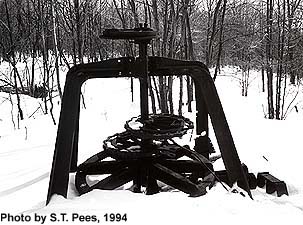

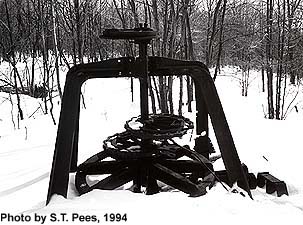

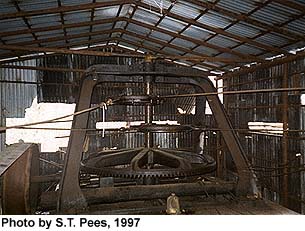

The power consists of an engine, a pulley and belt, and the power itself which is an arrangement of gears and eccentrics. The eccentrics provide the "to and fro" motion to the rod lines which are clamped to them and also are connected to the jacks (pumps) on the distant wells causing the jacks to move up and down, thus pumping the well. The power gears are usually in a frame which is characteristic of the maker and model. Band wheel powers, 14 to 18 feet (or more) in diameter (4.26-5.48 m) with the eccentrics under the wheel, are also common in the old oil belts and a few are still working.

In their heyday, engines for the powers had barkers which emitted a signature sound for each power when it was working. I remember these sounds in the oilfields. On crisp mornings in the late fall, the sounds would fill the valleys, each in its place in the musical score. You could even tell if the engine on the other side of the ridge was working or not. You could also hear sundry sounds caused by friction on the metal rod lines and from the pumping devices. A pumping lease creates a medley, soft to sharp, pleasantly repetitive, but one must be prepared for the staccato punctuations of the barker and backfires of the engine.

|

George Maloney experienced the halcyon days of early oil at Petroleum Centre on Oil Creek. He pumped wells and later became a clerk in the local bank, all this while in his teens. In 1879, at age 30 he established a manufactory of oilfield equipment in Franklin, Pennsylvania. This factory employed 60 men. The Franklin heavy crude field was quite active and a need for powers arose. Maloney made Iron King powers with the Iron King name. They somewhat resembled W.H. Emery and Son powers which were also made in Franklin. Maloney's plant was on the north end of the Thirteenth Street bridge at the base of Point Hill. In 1904, Maloney sold his factory to a group of oilmen who renamed the enterprise, Producers' Supply Company.

The power in this photograph was hauled to this spot next to a highway. It is not complete but the Maloney trade name can be clearly seen.

|

|

|

|

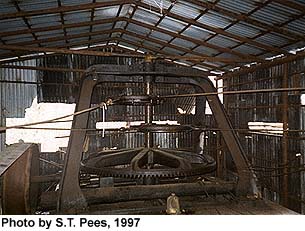

This power pumped Franklin heavy crude (31o API) from wells on the old Rial lease on the top and sides of Point Hill overlooking the Allegheny River and French Creek at Franklin, Pennsylvania. It was manufactured by the Producers' Supply Company. Producers' was in the Third Ward of Franklin, the part of the city that was heavily industrialized and known as "Little Pittsburgh" in the 1890's - early 1900's. Producers' was the former George Maloney works.

The model was the Iron King No. 1, made in 1904 or later. Only one rod line is left. The engine which was in the background has been removed and the pumper's shack has fallen down. The power was installed on the hill before 1910 and was used into the 1950's and possibly later. It was taken to its position on the hill via a tram which was earlier constructed by Edward Rial in the 1880's to transport heavy equipment to the summit.

Many of the old wells which were pumped by this Iron King No. 1 can be found around the crest of Point Hill. The wooden separators and stock tanks for some of them are still there.

|

|

|

|

E.D. Yates obtained a patent in 1880 for a push-pull central power. Via a series of inventions, his powers evolved to the 1896 patented gear-driven model pictured above. This power was on the flat bed of a truck when the photo was taken in Oil City.

|

|

|

|

Detail of the E.D. Yates 1896 central power.

|

|

|

|

This is an Oil Well Supply Co. iron frame power with two eccentrics. It is idle. Note pulley and loose belt at lower left.

|

|

|

|

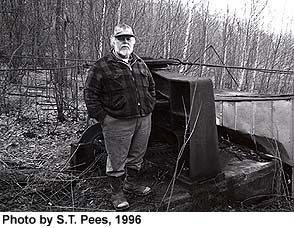

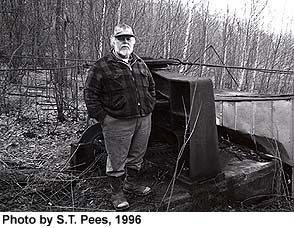

This is a Joseph Reid Gas Engine Company power made in Oil City, Pa. It has two eccentrics. This power is on the Huber lease and now pumps only five wells, one of which dates to 1865. It is operated by a 25 foot belt, 10 inches wide, and powered by an 1898 Reid 12 horsepower engine. Although the foundation is not level, it has been set "for conditions" and is even cantilevered so that excess strain is not put on any of the rod lines. Reid frames are massive, even have little shelves for parts. The galvanized metal runway for the belt is at right. Photo of William L. Huber at Plumer, Pennsylvania.

|

|

|

|

Knocked around by loggers, this Reid power still holds its ground, sort of. The rod lines are gone, but a large twisted mass of them were found not far off. It's hard to say who won, the bulldozer or the rod lines. Fly wheels of the engine are visible in the background where a field assistant is looking them over.

|

|

|

|

A bandwheel power. Powers of this type were made by the National Supply Co. (Toledo, Ohio), Joseph Reid Gas Engine Company (Oil City, Pa.), and other manufacturers. The eccentrics are underneath. Note rod lines close to the ground. First growth (quaking aspen) is taking over the site.

|

|

|

![]()