|

||||||

Dick Moon's Stories

May Sometime

Sam Pees, Kind Sir:

To relate my adventures on a Wolfe drilling rig, my granddad was a rig builder many years back. My dad had a pulling rig and followed the oil business so I guess the smell of crude oil got me involved.

As a young lad of 10 or 12 I saw an old gent named John Diamond drilling with a Wolfe rig and a steam boiler in the woods behind my house. The steam engine would hang up occasionally when the piston was on dead center and extended. You had to jump on the big flywheel to get it off center. Mr. Diamond showed me how to go about it (carefully) and which way to jump on the flywheel as it would run clockwise or counter clockwise. This started my fascination with Wolfe drilling machines. I shall never forget the smoke flying off the bull wheels' brakes when Mr. Diamond lowered the drilling tools.

In 1943 I got my driver's license and during school vacation that year I became a "toolie" on a Wolfe drilling machine on the Breene and Johnson oil lease. This was a real chance for a kid to make a few bucks, wow! The rig was powered by a four cylinder White truck engine. Other than dressing the drilling bits it was my job to run out and stamp the leaves which would catch on fire from the truck exhaust. The driller was a gent named Wilber Rogers, long gone. Running the bailer, he always had binder twine on the sand line at different levels to see how much rope was coming out of the hole. A friend walked in, a bull session got underway and the bailer, unnoticed, came up too fast and went over the crown pulley. What goes up must come down. We all took off with our hands over our heads and the bailer lit in the woods. It looked like a pretzel.

Instead of canned motor oil, Mr. Rogers always brought Second sand crude oil from a Rocky Grove well to put in the crankcase of the engine. I thought it would cause the engine to burn up, but much to my amazement it worked fine, just like he said it would.

To further my experience I heard during Christmas vacation that they were ready to shoot a well that Mr. Rogers had drilled, so I stopped down. A guy from Ellis Torpedo Company came down with the glycerin. He was the shooter and right away pulled out two cans of nitroglycerin from his truck. Being winter he was wearing a long overcoat and part of it had draped over the duck board. He unknowingly set the two cans on the board on top of his coat tails and jumped off. The cans both went "bonk" on the frozen ground. Anybody standing by, if they were dark complected, went as white as a bed sheet.

Mr. Rogers was a fine gentleman, like a second father to me. Also like a marine instructor.

|

August

Sam, Kind Sir:

Liken to the military service, we remember the good and humorous times rather than sad times. So I shall relate some stories. My granddad told me a story about working 12 hour shifts on an oil rig. To get a jug of water they walked down the road a ways to a house. There was a fence and a vicious police dog at the house, so they had to get the ladies attention to tie up the dog and let them fill the jug. On one trip a hobo, or so called tramp in those days, happened along looking for a handout. He told my granddad that the dog was no problem, all you have to do is scare the dog more than he scares you. With that he opened the gate and got down on all fours and chased the dog howling behind the house (never tried that).

Another gent, long gone, built a winch, the Myers winch, had it patented. About every Fordson tractor had a Myers winch on the back for pulling wells. Someone else copied his winch so Myers went to Chicago with his lawyer. The other side had several lawyers, and Myers lost because the other man's winch had one more (or less) tooth on the main gear.

On these river hills they generally had a pole attached to the front and rear axle extended so if the tractor reared, the pole slapped the ground avoiding an upset.

My dad worked for David B. McCalmont for many years. With some Fordson tractors scattered around the oilfield he one time told me if he had those Fordsons in high gear when he cranked them, he could have traveled across the world, discounting that those old boys built a fire under them in the winter time to loosen up the crank and get the engine in the mood for the cranking ceremony.

History was made locally, such as Fogan elevators came from a local guy, the Milton King pulling machine came from a local person. A local fellow, Merve Bolles came up with a spudder that was driven by a car tire, friction-drive if you will, replacing belts. I'm told that he also came up with a coil spring on the crown pulley to replace the old rope "cracker" used on machines to absorb shock.

As to steam boilers, many old gents used them with a steam engine to power their sawmills. They burned the slabs off the logs in the boiler, and I guess that could be called recycling. I should also mention that all these boilers had steam whistles on them which were used mostly to determine lunch time and also could be set off in case of an accident.

All of these fine old drilling machines were replaced by spudders such as Keystone, Cyclops, etc. as they drilled faster, easier to move, and were powered by an onboard engine.

When I was a lad about 16 or such, there was a place on Victory Heights, Route 322 near where the Cranberry Mall is now, called Pine Hedge Cabins. A gas well watered out and a friend of my dad volunteered me to help the guy with a pulling rig. No gas for the cabins. A few bucks to a kid sounds great, so I helped this guy bail the well from midnight till morning. Two inch tubing which probably had a packer down the hole to shut off water around the tubing and casing. As it was, we had an inch and a quarter bailer to run inside the tubing and down to the water. It was at night. Try to imagine a thin sixteen foot, one and a quarter inch bailer, bringing up perhaps 2 or 3 gallons of water per run. I guess it was iron machines and iron men.

I mentioned the Milton King pulling machine. It was invented or patented by Mr. King of Bredinsburg. It was on a 4-wheel wagon and was pulled up beside the well and swung sideways and raised.

|

November Sometime

Dear Sam,

Maybe you know that on the Wolfe rig the driller had a drilling bench. The first bench was possibly 3 feet off the floor and the second seat or stage was probably 6 feet off the floor. The driller ran a "screw" which was about 8 to 9 feet long and as the drill proceeded, he lowered the screw with a handle affair. As I recall later on they had a rope "cracker" about 30 feet long which absorbed the shock and he lowered the tools with the bull wheels as the depth increased. I'm sure you've seen the giant bull wheels, and when he lowered the stem and drilling bit the smoke would roll off the bull wheel due to a brake band that matched. The brake handle was probably 5 feet long with a slot in the end which he chained to the drilling floor to hold and could be released a tad as needed. They also had a tool with a circle on it for dressing the bit so you could size it so it would go in the hole or fit in the casing. The bit being cherry red of course as you sledged it sharp at the forge.

Another time somebody kept stealing gasoline out of a 55 gal. drum we had at the rig. When it was almost empty, the driller told us to hide the new drum which had just arrived. We put 20 gallons of water in the old drum and left it in its customary place. Would you believe a neighbor came up on the drilling platform next day just to talk and told us that he missed work, he had water in his gas.

I recall that my dad and many other men pulling wells got to where they wouldn't pull on the old gin poles at the wells. They had spikes to crawl up to the pulling block, and eventually they became so dangerous due to rot, etc. that the men dragged the poles down and used the pulling derrick.

I might also relate this story to you about wells out in the river. Between Oil City and Reno my dad and I were pulling a well on an island, but we were set up on the opposite bank. At the time the Pennsylvania Railroad had a tower in Oil City. We had the tractor setting on the yon side of the tracks with the cable going to the island well. We put a loop on the winch cable so we could pull it off if a train came. What we didn't know was that every time the cable slacked it made contact with both rails indicating that a train was coming, but not coming. A track walker came down and told us, "please guys, put a board on one of those rails."

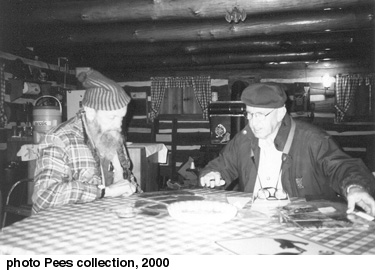

This story goes on back a few years. The pumpers from Quaker State and Pennzoil always had a Christmas party in some old tin powerhouse with a burn barrel. I was always invited and finally suggested we have it at my log cabin. So it has come to pass that the party is held at my cabin in December this year because the cabin is still warm from the doe hunt. So with that, I wish to invite you and any guest you might wish to bring along. I'm sure it would prove educational to you. It has turned into a blue grass band, practice session and a few guys play poker. It has become a limburger party also. Much other food too, and I personally am not a limburger person. So if you choose to show up, bring no food.

|

|

||

|

![]()

| © 2004, Samuel T. Pees all rights reserved |

|