|

||||||

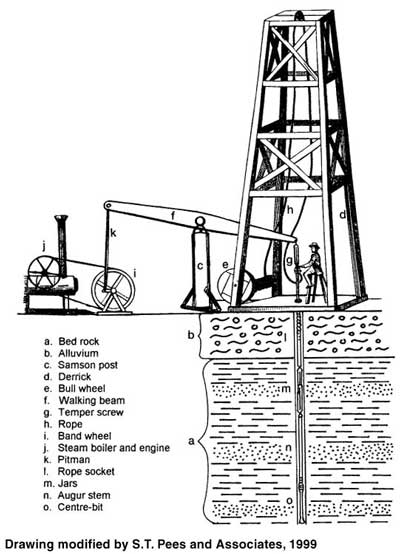

Walking BeamThe history of the walking beam in America is a little hazy. Apparently it was nearly contemporaneous with the spring pole. The known use of a walking beam dates back to the early salt days of ca.1810 and continued in use through the rest of the 1800's and well into the 1900's even through WW II and, in another form, to the present. The walking beam was part of the standard cable tool rig in the 1870's and later . The walking beam was securely held up by a samson post (also spelled or mispelled sampson) which was either set deeply into the ground or held by beams which were built into an outside extension of the derrick floor. Different dimensions of this important device were used over the years and were brought about by available space (closely drilled oilfields were very cluttered) or the preference of the rig builder or driller. The walking beam achieved a manner of standardization when it became a part of the so-called standard derrick or rig. |

||

|

||

|

The early samson posts were usually 8 to 10 feet high. The center of the walking beam balances in a saddle on the post and moves freely due to a center pivot. Thus the up and down motion of the walking beam can be achieved as soon as a pitman, bandwheel and power are hooked up (see illustration above). The early walking beams (before standardization) were 16 to 20 feet long and about one foot thick in the middle. By 1884 the standardization of the wooden drilling rigs (the standard cable tool rig) was clearly achieved and the specifications of a carpenter's rig was in print as noted in an Oil Well Supply Company (Pittsburgh and Oil City, Pa.) catalog of that year. However, slight variations were still present depending upon the rig builder (or manufacturing company) and, later, on the region where it was to be used such as California, Appalachian Basin, Canada, etc. The standard rig walking beam was 26 feet long and was 12 inches wide by 26 inches thick in the middle and bevelled to one foot or 14 inches square at each end. The samson post was 13 feet high, 18 inches by 20 inches thick at the base and 18 inches square at the top. |

||

|

||

|

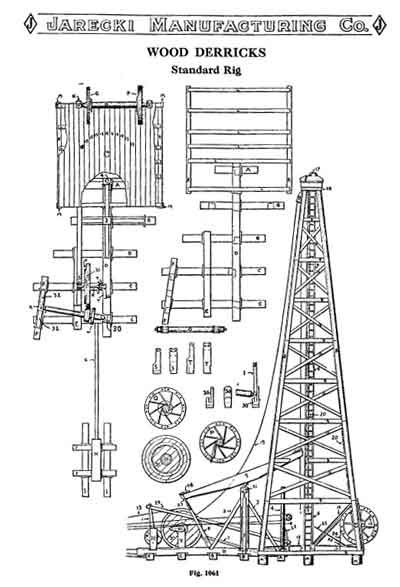

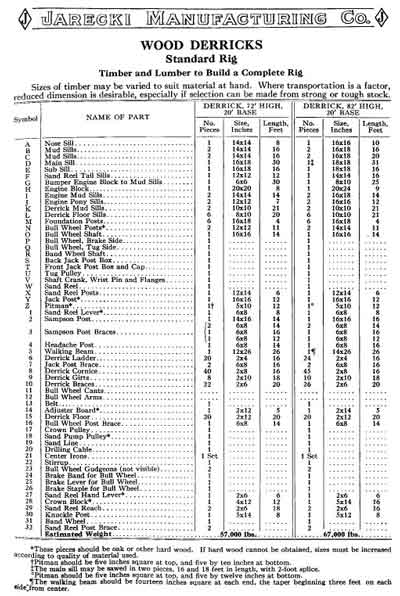

According to the above illustration and specifications in the Jarecki catalogue, the standard derrick was produced in two sizes, 72 feet or 82 feet high. Reduced dimensions are possible according to a note at the top of the spec sheet. The walking beam concept continued on into the portable spudders and drilling machines of the 1920's, 30's, 40's and 50's. Some of the old abandoned portable rigs in America's early oil belt (i.e. Pennsylvania) still have the weathered remains of their wooden walking beams. |

![]()

| © 2004, Samuel T. Pees all rights reserved |

|