|

|

Bailer

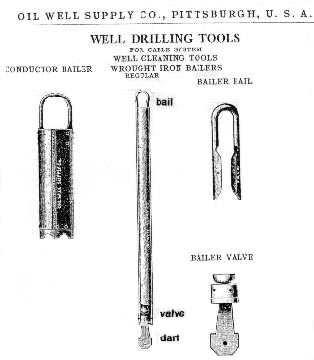

As percussion drilling progressed in the hole, the amount of rock debris (cuttings) at the bottom increases and reaches a point where it had to be removed to expose the fresh surface of the bed rock in order to allow drilling to effectively continue. Cleaning out the cuttings was done by a bailer, a special tube or light pipe 6 to 30 feet long. The device was also called a sand pump and had its own line (sand line) which spooled on the sand reel on the derrick floor, rose to a pulley at the top of the derrick and came down to fasten to the looped grip (called the bail) on the upper end of the bailer. The bailer was allowed to run to the bottom of the hole to retrieve the sediment.

The principle of the bailer is as follows: the regular bailer has a dart valve at the bottom, with the dart protruding several inches below the tube of the bailer. The bottom of the hole has water in it, if not, water has to be dumped in the hole. When the dart touches the bottom, it pushes upward and opens a hole in the bailer through which water and cuttings are sucked in. The hole closes when the bailer is lifted thus allowing the cuttings to be brought to the surface where they are dumped in a slush pit. Bailers are still used when drilling water wells.

|

The pictured bailer is in Jarecki Manufacturing Co. catalog no. 50.

|

|

|

|

The bailer tool is easily identified by the looped bail at the top and the protruding "dart" at the bottom. The cup valve is in the bottom. A 3 1/4 inch bailer is used in a 4 inch hole. The length of the pictured bailer is 19 feet and the weight is 94 lbs. After Oil Well Supply Co. catalog no. 32, 1913.

|

|

|

|

A bailer left at an old well site. The dart protrudes from the bottom. A wild grape vine coils over the tool.

|

|

|

![]()