|

||||||

WW II

All means of transporting oil and product in bulk, especially aviation gasoline, were put into service in the U.S. during the World War II years, 1941-45. Some experience had been gained during the prior emergency of the Great War, 1914-18 (the U.S. entered in 1917), but WW II was a much more massive undertaking as well as being fought on two gigantic fronts. Fortunately, as far as demand for refined oil and gasoline was concerned, the peak year for the Pacific front was 1945, particularly the months of May and June, while the major shipments to the U.S. East Coast for the European Theatre occurred before that, the peak being mid-1943.

The oil run via tank cars to terminals on the U.S. East Coast can be best described as originating at Texas refineries and terminating at ports where the refined product (mostly aviation fuel) could be loaded aboard the ocean-going tankers. Tank car shipments of petroleum products to the East Coast built up to 1,000,000 barrels per day at the peak compared to a prewar high of 60,000 barrels per day and a mere 5,000 barrels some years earlier (Look, 1946).

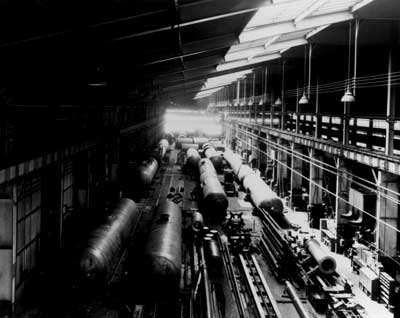

In order to move one million barrels daily by rail to the East Coast, a much heralded tank car fleet of 74,000 cars were put into use and an operating system was planned and carried out. An idle tank car wasn’t to be seen. The tank cars were moved in long solid trains of up to 70 cars. Transport of the aviation gas was not interrupted for the entire distance from the Texas catalytic cracking tower to the Atlantic port. Actually at the outbreak of the war in Europe, the U.S. had 115,000 railroad tank cars, but 41,000 of these had to serve purposes other than the East Coast run.

The tank car situation prior to WW II was based on competition between oil companies. All cars, leased or otherwise obtained, would go to the refineries or terminals of the owning company, hence there were cross runs, idle time and duplicate purposes if viewed from a single standpoint. A joint cooperating system was devised under the Petroleum Administration for War. The system eventually saw tank cars deliver nearly 70% of the total oil and product placed at the Atlantic Coast. The means of freeing up tank cars for the long runs was accomplished by pooling terminals, stopping cross hauls, doing maintenance faster, using highway tank trucks for short hauls (200 miles or less), and giving priority or clear track to the tank car trains, meaning that they wouldn’t be rerouted or put on sidings to await their turn (Look, 1946). Oil products, especially the loads of gasoline, dominated the rails during war time.

When the U.S. geared for the final invasions of the war in the Pacific in 1945, the tank cars were available because the East Coast demand (Europe) was lessening. Looking backwards, it wasn’t until December, 1942, (one year after Pearl Harbor) that shipments to the U.S. west coast exceeded 10,000 barrels per day and not until July, 1943, that they exceeded 20,000 B/D. By May and June, 1945, nearly 170,000 barrels per day were hauled by tank cars to Pacific Coast ports.

|

||

|

![]()

| © 2004, Samuel T. Pees all rights reserved |

|