|

||||||

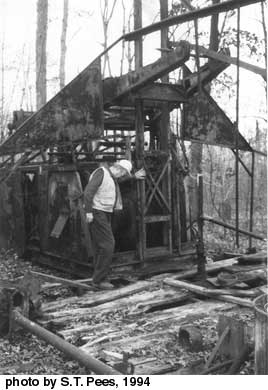

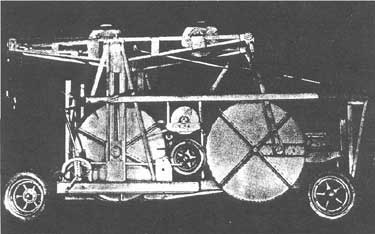

Bolles Rig

In the 1930's, M.E. Bolles of Pinoak (near Seneca, Pennsylvania) patented a dual friction drive drilling rig. According to Producers Monthly of Dec. 1938, the unusual rig attracted visitors from "virtually every oilfield in the country".

The rig was mounted on a metal frame with rubber tire wheels. It had a telescopic mast. The absence of belts and chains reduced the operating space and made it a very compact unit. It was enclosed by sheet metal. An engine at the rear drove two automobile wheels with tires which were connected to a universal assembly, thus allowing rotation in both directions. The tires were in contact with dual bull and band wheels and effected the friction drive in that manner. The Bolles machine had a self-centering walking beam and a universal-driven sand reel. It had ball bearings for all moving parts.

According to the Producers Monthly article the first well using a Bolles was drilled to 1080 feet 9 inches at an average penetration rate of 7.5 feet per hour. The well was completed in the Venango third sand.

The Bolles rig, as such, had a short history. However, automobile wheels with rubber tires used for friction drive are seen on a number of old rigs in the Pennsylvania oilfields.

|

||

|

![]()

| © 2004, Samuel T. Pees all rights reserved |

|