|

||||||

Leidecker

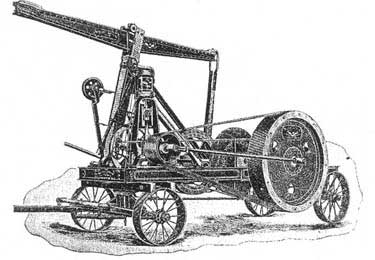

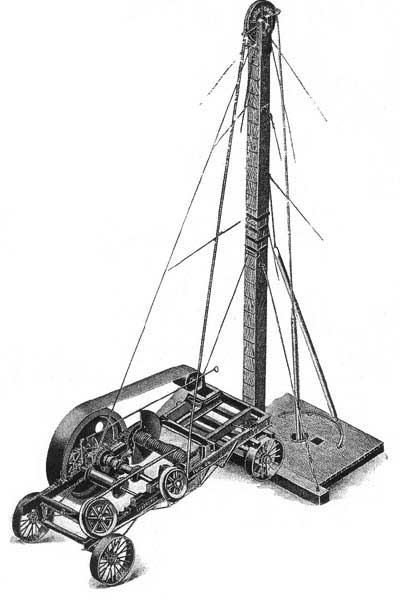

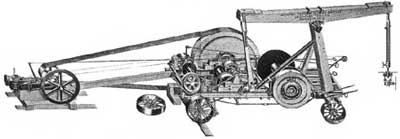

The Leidecker Tool Co. of Marietta, Ohio, made drilling machines and oil well supplies. A 1906 model is pictured immediately below. By 1923 they had five sizes listed in their K catalog. Four of the models (sizes) were numbered according to their depth capacity rating which was based on the amount of 2 1/4 inch manila rope that could be spooled on the cable spool: No. 14 = 1400 feet, No. 16 = 1600 feet etc. The capacity would be greater if wire rope was used instead of manila rope. No. 24 had a rated depth capacity of 3000 feet and was their largest size in 1923. However, 2 1/2" manila rope, instead of 2 1/4" was preferable for this deep rig, changing the spooling capacity to 2400 feet and the actual depth to 2200 feet.

The rig frames were made entirely of structural steel. According to Catalog K, "castings and other parts were of cast steel, deep forgings, and malleable or high tensile strength cast iron". Some essential parts continued to be made of wood due to its elasticity (according to the manufacturer). These included the band wheel, brake wheel, samson post, pitman and mast. In this respect the Leidecker machine is not unlike the construction of rival makes on the percentage of wood to metal with wood remaining the favorite material for many heavy duty parts (not gears).

All sizes except No. 24 had a vertical steam engine mounted in the front. No. 24, the largest size model, had a Leidecker horizontal steam drilling engine mounted separately behind the rig. The boiler for No. 24 was placed at a distance behind the engine if space allowed.

The mast for the various rigs was the single pole type, 60 feet high. A special A-frame mast was made preferably for model No. 24 and obtainable by request.

The company's byword as printed on every page of their 1923 K catalog was ' "LEIDECKER", another word for satisfaction'. Judging from testimonials by drilling contractors and oil companies, Leidecker had a good number of machines working in Ohio, Oklahoma and Wyoming in the 1920's and to varying extent in other basins, even a foreign trade. A photograph in Catalog K shows a No. 16 machine at work on the African coast.

By 1930 (or before) the No. 24 machine was put out by Ideco-Leidecker, essentially with no changes. IDECO was the name used for the International Derrick and Equipment Company. They associated with this model because of its depth rating, a unique and patented spudder attachment and the independent calf wheel to name a few.

|

||

|

||

|

||

|

| © 2004, Samuel T. Pees all rights reserved |

|